What is CNC?

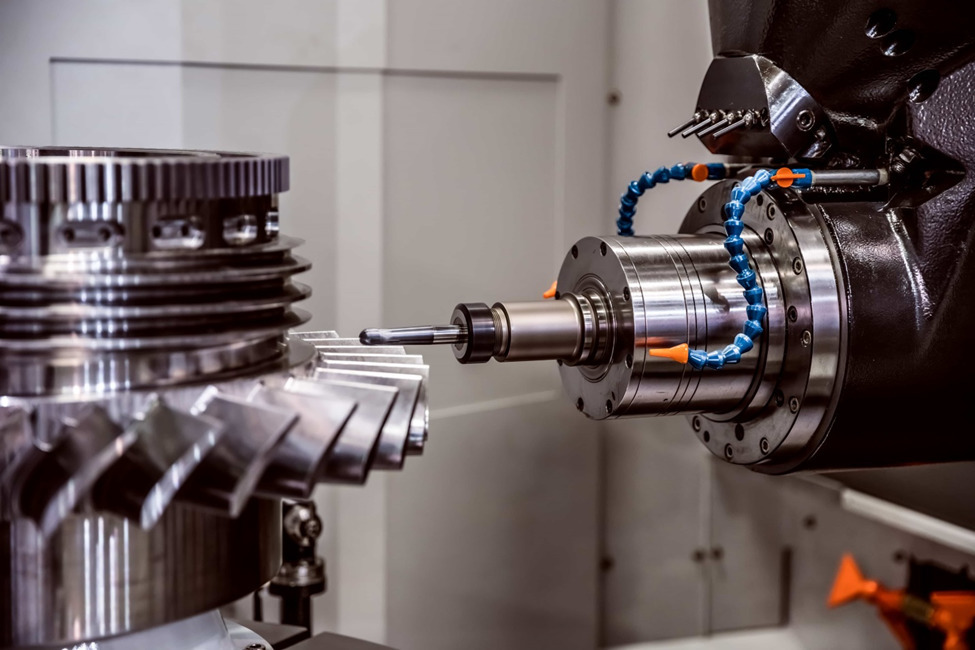

Computer Numerical Control or CNC is the automated control of machining tools to improve their efficiency in working and improvise the quality of work done by them over their respective job pieces. CNC machines combine the machine tool with a controllable platform running on circuital systems and numeric codes given as inputs by the user. It accepts the CAD model of the target job piece and converts them into alphanumeric codes. In today’s time of automation, the importance of CNC is hugely immense and there is not any field where it does not find its application. The article discusses further cnc machining services and their basic features.

Benefits of CNC

The cnc machining services have the following advantages when compared to their traditional counterparts: –

- Very high levels of accuracy and precision with the least tolerance or deviation in the dimensions.

- Repeatable processes with hardly any time wasted for changeover of the equipment.

- Can be operated on a wide range of materials like metals, non-metals, alloys and plastics.

- Ideal generally for low volume job pieces, but the accuracy and finish will be of superior quality.

- Very less material wastage and overall good material and job management.

The major industries that benefit due to the advancement of the cnc machining services include automotive, aerospace, medical, consumer electronics, manufacturing, aviation, computers, robotics etc.

The major services

The major of the cnc machining services include the following: –

- CNC Milling- In a milling operation, the jobs are done on a single solid piece of raw material where the cuts and operations are done at precise points such that the optimal amount of material is removed and the final piece is as per the desired CAD model. The best thing is that they can do very complex jobs also. The material wastage is the least and the production time is very less, hence meeting all of the deadlines properly.

- CNC Turning- It is another major service where the manufacturing process is very fast, simple and accurate in nature. They remove the excess material easily via cuts, grooves, and other suitable job processes. All it requires is an input of the CAD model and then it gets converted to alphanumeric codes that ease up the overall process.

Majority of the industrial applications involve a culmination of both of these services. They perform the ideal operations in the desired manner over their respective metal workpieces and the end product turns out to be highly accurate and flawless in nature.

A common choice of materials

Although CNC can take the input from a wide range of materials, still there are some materials that are more commonly used. These are copper, titanium, polycarbonate, ABS, Aluminium, Magnesium, Brass, nylon, acrylic etc. The machining parameters differ from one type of material to the other and hence the user needs to study properly about the working on these before performing any operation.

These days one can find easy quotations on cnc machining services and one can choose the best as per his or her requirements.